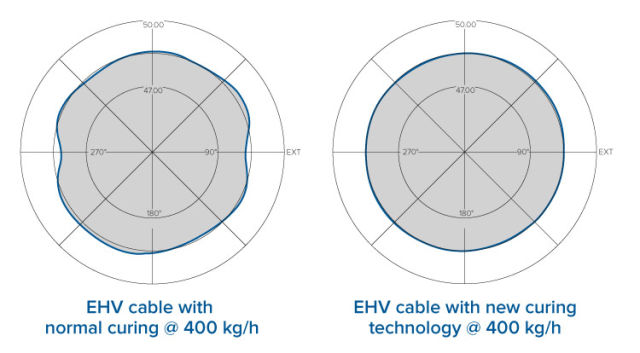

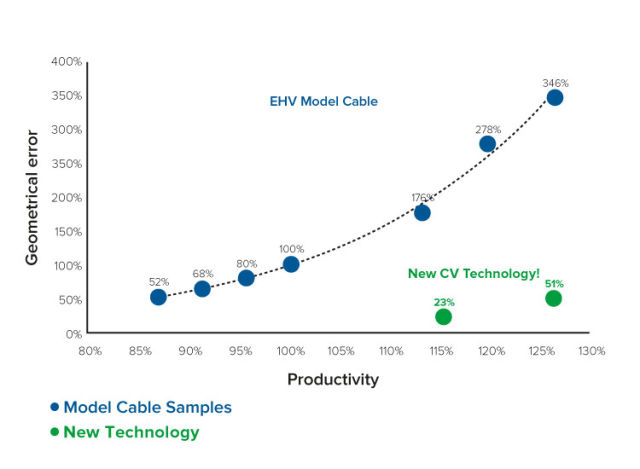

Optimal roundness is essential for efficient use of insulation material on a CV line. Cutting down material overuse is one of the biggest contributors to production productivity in pre-molded and pre-fabricated joints and terminations as well.

Our Round Value Package Premium is tested with more than 25 strictly controlled and comparable trials. The new revolutionary curing technology increases VCV line curing capacity and simultaneously improves HV and EHV cable core roundness.

14.7.2025

Here is a robust cutter for your larger extruded pipes. Our CMC 75 is designed to cut rigid multi-layer PO, PEX, and PE-RT pipes into bars. Achieve precise cuts, each and every time. Read more

30.6.2025

Another crosshead joins the ranks of automatic centering for extrusion of cables. The ACC 12/16 achieves exceptional concentricity, resulting in optimal material usage and less waste. Read more

18.6.2025

Precise cuts, safety, and ergonomics ensure the finish quality of pipe & tube. Cutters are available as for extrusion line upgrades or complete line integrations. Read more

18.6.2025

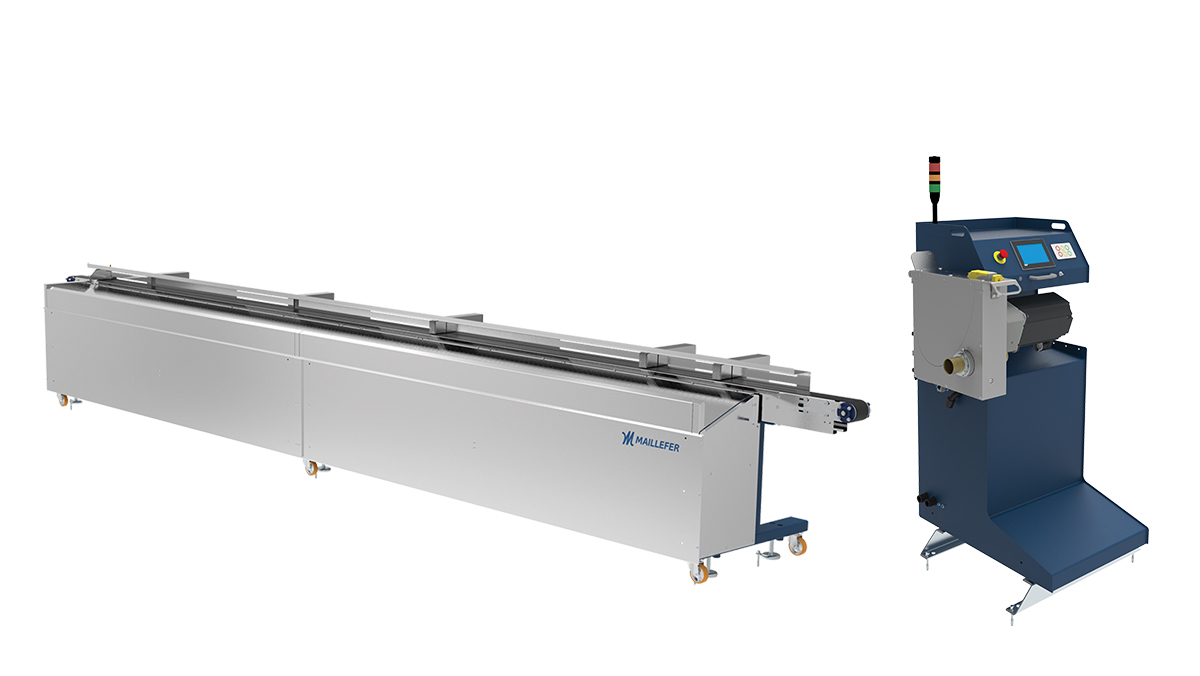

Intelligent induction finds its way in XLPE cable production. It represents an additional building block of smart innovations being placed in manufacturer’s hands. Read more

23.5.2025

One of the many challenges of producing medical tubing is the use of flexible materials. Improve diameter stability and concentricity coming from extrusion without sacrifice. Read more

13.5.2025

The promise for exceptionally high productivity without losing on cable quality may raise eyebrows. Yet, several customers have made the leap of faith towards rapid crosslinking. Read more

29.4.2025

More heating & plumbing pipe with less EVOH is possible with our five-layer PXL line. Extrude ultra-thin, low mol% EVOH for 5 or 3 layer PEX-b or PE-RT pipes. Read more

9.4.2025

Serving multiple markets like heating & plumbing, fiber-optics microducts, medical tubes, automotive tubes, oil & gas and more, means building on commonalities and responding to the specificities. Read more